Maize

Genetics Cooperation Newsletter 80. 2006.

Physical characteristics of different types of maize kernels

--Gadag, RN; Jha, SK; Singh, A

Maize is considered an important cereal crop serving as a staple food to a large population spread over parts of Africa, Asia, North and South America. It is the most diversified of all cereal grains in terms of its application. Maize is utilized for human food, industrial processing and as a feed ingredient for animal rations. Various types of maize, classified by characteristics of their kernel endosperm, have been developed, including field (flint and dent), flour, popcorn, sweet and waxy corns. These are found to exhibit a specific pattern of distribution of endosperm in respect to content and component of starches (hard and soft), which determines their end uses (Hallauer, A.R. (Ed), �Speciality Corns,� SRC Press Inc., Boca Raton, USA, 1994. Pp 410). Kernels of these different types of maize can also be visually distinguished due to their characteristic features.

Physical characteristics of food grains are important in association with the design of a specific machine or analysis of the behaviour of the product in terms of handling and storage, and in the development of new consumer products. Fifteen genotypes of maize grain field (flint), sweet, and popcorn populations were evaluated for the physical characteristics of bulk density, true density, porosity, 100-grain weight, hardness and terminal velocity in the present study. An attempt has been made to relate these properties to the known features of different types of corn, heir specific usage and possible implications.

The average bulk density was measured by gently filling a 1000 cc container with the grain and then weighing it. The average true density was determined using the toluene displacement method (Mohsenin, Gordon & Breach Science Publishers, 1970). Porosity of husk was computed from the values of true density and bulk density using Eq. 1.

ε = [1-(ρb/ρt)]x100 �(1)

where, ε = porosity, per cent

ρb = bulk density, kg/m3

ρt = true density, kg/m3

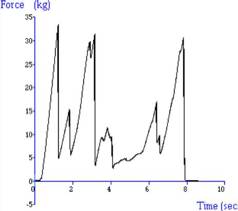

The hardness was measured as the first peak force recorded while a grain was compressed by a probe incorporated in a Texture Analyzer (Model TA+Di�, Stable Micro Systems, UK). The test speed of the probe was set at 0.5 mm/s and compression of grain was programmed for up to 60%. Five grains were compressed and the maximum value of first peak force recorded from force-time diagram among 5 grains was taken as the hardness of the grain. A typical force-time diagram is given in Figure 1. Terminal velocity was measured as the minimum air velocity at which the grains remained suspended in air.

Physical

characteristics determined for 15 genotypes of maize at an average moisture

content of 9.78% (wb) are presented in Table 1. Bulk density, which is an important parameter for

determining the volume of storage containers, was found to be in the lowest

range for sweet corn genotypes, except for the genotype in plot no. 963. Field corn genotypes had an

intermediate density, and the popcorn genotypes had the maximum density. A majority of the sweet corn genotypes

had the lowest true density, while the popcorn genotypes had the highest. Porosity values, which provide a

measure of water requirement during any hydrothermal

Figure

1. Typical force-time diagram for

determination of hardness of maize kernels.

Table

1. Physical characteristics* of

selected maize genotypes.

|

Genotype plot No. (Kharif-05) |

Grain type |

Bulk density (kg/m3 ) |

True density (kg/m 3) |

Porosity % |

100-grain weight (g) |

Hardness (kg) |

Terminal velocity m/s |

|

957 |

Sweet corn |

653.4 |

1276.3 |

48.80 |

15.14 |

37.83 |

12.0 |

|

958 |

666.6 |

1316.9 |

49.38 |

15.93 |

47.10 |

12.5 |

|

|

959 |

549.6 |

1112.9 |

50.61 |

16.30 |

41.65 |

11.0 |

|

|

960 |

525.0 |

1070.4 |

50.95 |

14.26 |

31.95 |

9.8 |

|

|

961 |

563.4 |

1127.7 |

50.04 |

13.41 |

32.65 |

10.0 |

|

|

962 |

610.2 |

1113.8 |

45.21 |

12.25 |

32.83 |

9.9 |

|

|

963 |

743.8 |

1226.7 |

39.36 |

23.30 |

32.32 |

13.5 |

|

|

964 |

Field corn (flint) |

718.8 |

1293.9 |

44.44 |

25.87 |

37.77 |

14.5 |

|

965 |

736.2 |

1217.9 |

39.55 |

20.58 |

32.70 |

13.5 |

|

|

966 |

762.2 |

1308.0 |

41.72 |

23.89 |

63.33 |

14.5 |

|

|

967 |

Popcorn |

797.2 |

1287.0 |

38.05 |

13.54 |

40.73 |

13.5 |

|

968 |

772.6 |

1303.2 |

40.71 |

16.12 |

44.71 |

13.7 |

|

|

969 |

711.0 |

1288.2 |

44.80 |

17.40 |

43.13 |

13.4 |

|

|

970 |

744.6 |

1270.9 |

41.41 |

13.84 |

40.90 |

13.7 |

|

|

971 |

742.8 |

1352.8 |

45.09 |

16.85 |

34.75 |

14.2 |

*Physical characteristics were

determined at an average moisture content of 9.78% (wet basis).

treatment, of sweet corn genotypes were the highest among the 3-grain types, except for the genotypes in plot no. 963. 100-grain weights of field corn genotypes were the highest followed by popcorn and sweet corn genotypes.

Grain hardness plays an important role in product formulation and development of machines such as grinders, de-germers, etc. In general, hardness of popcorn and field corn genotypes was found to be greater than that of sweet corn, except for the genotypes in plots number 958 and 959. Characteristically, the genotype in plot no. 966 (field corn) was found to be the hardest, whereas the genotype in plot no. 960 (sweet corn) was the least hard.

Terminal velocity of grains is considered important for its separation with other grains. Sweet corn genotypes, except for the genotype in plot no. 963, had the least terminal velocity compared to popcorn and field corn genotypes.

Perusal of the results indicates some distinction of the sweet corn genotypes (lower hardness, test weight, bulk density and terminal velocity and higher porosity) from the other two types of corn. This may be related to and reflected by lower accumulation of starch in the kernels of these genotypes due to specific endosperm mutations (Coe and Polacco, MNL 68: 157-208, 1994). This property, if confirmed by further studies, may be useful as a selection criteria for maize breeders, especially in efforts to convert field corns into sweet corns. It is relatively difficult to separate flints and popcorns on the basis of the physical characteristics elaborated above. This may be attributed to the presence of both hard and soft starches in popcorns, determining the popping property. Thus, there may not be a simple relationship between the physical characteristics of the kernels and popping features of popcorn.

_________________________________________________

Please

note:

Notes submitted to the Maize Genetics Cooperation Newsletter may be cited only

with consent of the authors.

Return to MNL 80 on-line index.

Return to MNL index.

Return to MaizeGDB home page

____________________________________________